A deaerator is a deaeration device that is used in the steam production system to remove water-soluble gases. Another function of the deaerator is to preheat the feed water of the boiler.

In the deaerator, steam and water are in direct contact with each other therefore, according to the laws of fluids, the partial pressure of steam in water increases, and as a result, the partial pressure of other gases dissolved in water is equal, and thus the gases are separated from water. It should be noted that the increase in water temperature is directly proportional to the decrease in dissolved gases in water Heating the water to 82℃ reduces the oxygen content to less than 2 ppm. And at the boiling point of water (100℃), this value reaches 0.007 ppm.

The reason for using a deaerator

If the water entering the boiler is cold, when it enters the boiler, a thermal shock will occur and cause damage to the boiler. Also, not using a deaerator causes gasses dissolved in water to be unable to leave the water and corrosion occurs in the boiler. The presence of oxygen causes corrosion and the presence of carbon dioxide causes the pH of water to decrease and water to become acidic.

In the processes where steam is used for stripping, the presence of oxygen not only disrupts the stripping process, but it will also cause odor due to oxidation in the solution. When the deaerator for any reason is disable to separate the dissolved gases in an optimal way, chemicals such as hydrazine and sodium sulfate can be used to optimize the result of the process. When chemical materials cannot be used, pressurized deaerators should be used. The presence of a deaerator when the reverse rate is more than 25% of the boiler feed water and it is required to be more than 110℃. For every 10℉ increase temperature of water entering the boiler, the deaerator reduces the fuel consumption of the system by approximately 1%.

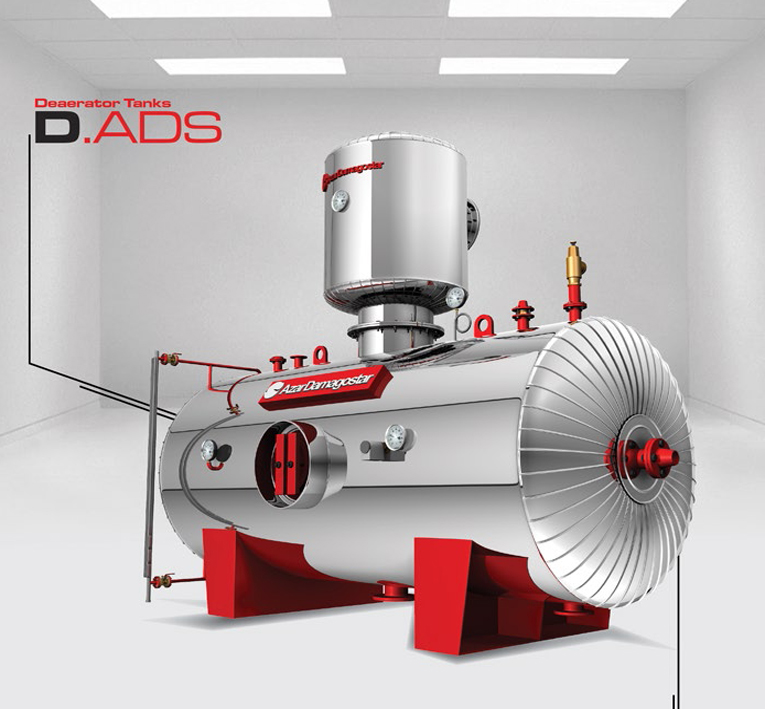

The details of the basis of the work of deaerator of Azar DamaGostar company:

The deaerator system has six pipping circuits, the functioning of the de-eritor is explained in these six circuits. The main task of the deaerator is to remove insoluble and non-condensable gases and preheat the boiler feed water.

Reverse condensate water flow

After the reverse condensate passes through the pipping circuit, the fluid enters the deaeration tower and it is sprayed on the packings by the spray valve. The fluid is in direct contact with the steam from the moment it is sprayed, which is the main factor in the separation of insoluble gases from water. After the water is sprayed on the packings, the liquid moves down in the form of drops inside the deaeration tower and enters the scrubber.

In a turbulent flow with steam, it loses its insoluble gases, also in this interaction water and steam exchange heat and the water reaches the desired temperature in terms of temperature to enter the boiler.